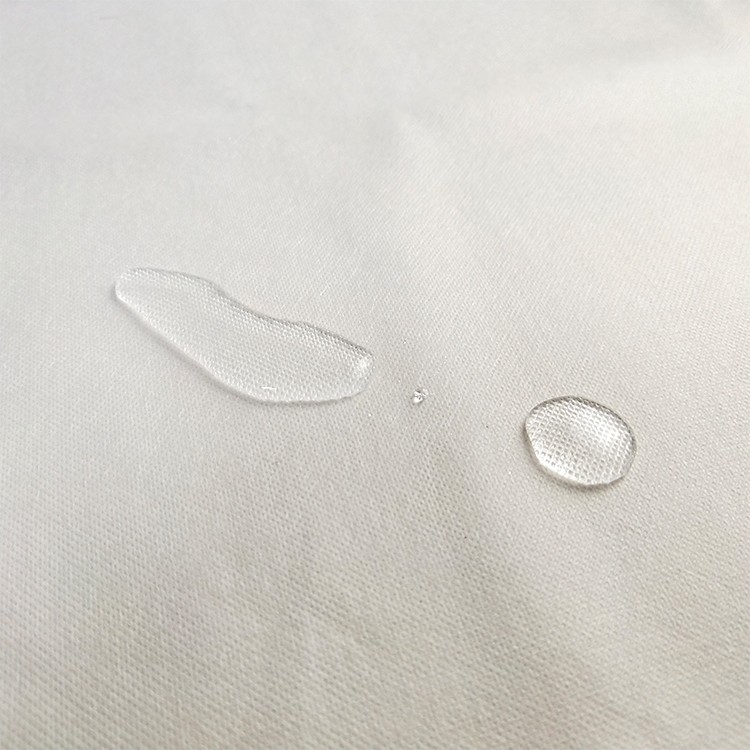

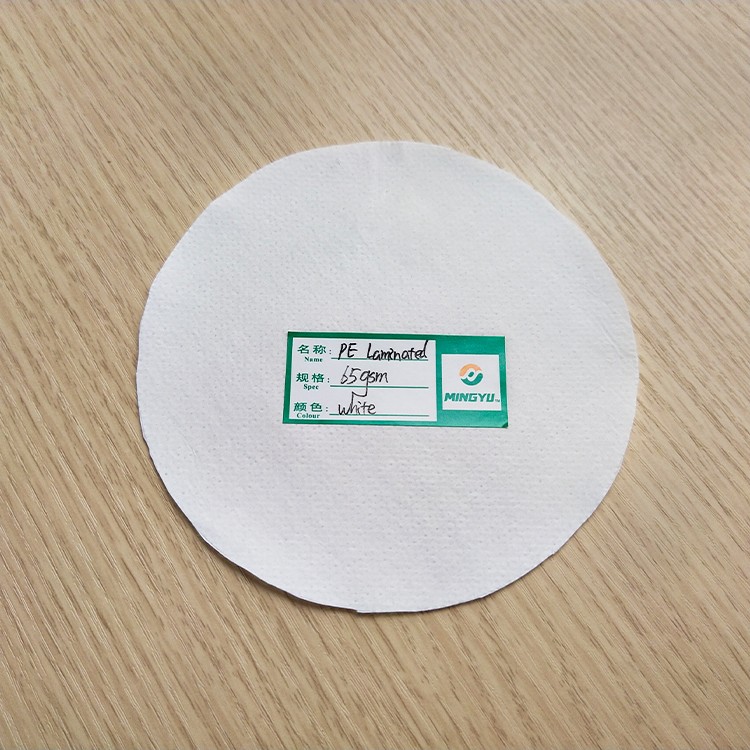

The PP+PE fabric is a film-coated non-woven fabric, which is characterized by: airtight, waterproof, good bacteria-inhibiting effect, and obvious distinction between the front and the back. The side that is in contact with the body is a non-woven fabric, which is non-allergenic and feels good. There is a layer of plastic film outside to prevent liquid leakage, which is used in occasions with pollution and viruses. The main use of the hospital infectious ward is the film-coated non-woven protective clothing.The role of Mingyu medical protective clothing: The main role of the protective clothing is to isolate bacteria and viruses, and prevent medical workers from being splashed and infiltrated by droplets, blood, body fluids, secretions, excreta, etc. of infectious disease patients at work , So as to achieve the purpose of protecting the health of medical staff from viruses.

Copyright © 2025 Hunan Mingyu Nonwovens Co., Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.